Chrome Corundum Grinding Wheel

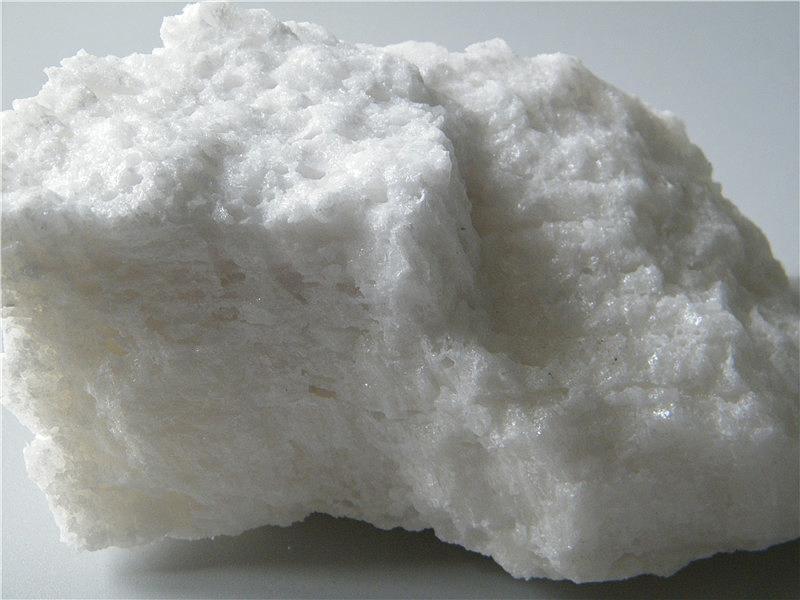

Chrome corundum grinding wheels are suitable for processing high-strength materials such as high-speed steel and alloy steel. The cutting efficiency is higher than that of white corundum grinding wheels. They are widely used in tool grinding, internal and external cylindrical grinding, and grinding of instrument parts. Production Process Chrome corundum grinding wheel code (PA) is made of industrial alumina powder as the main raw material, adding an appropriate amount of metal oxide, and smelted in an electric arc furnace. Its color is light rose red, its hardness is similar to that of white corundum, and its toughness is higher than that of white corundum grinding wheel. high. shape The shapes are divided into flat grinding wheels, double-sided concave grinding wheels, double bevel grinding wheels, cylindrical grinding wheels, disc-shaped grinding wheels, and bowl-shaped grinding wheels. According to the machine tool structure and the needs of grinding processing, grinding wheels are made into various shapes and sizes. Table 6 shows the shapes, sizes, codes and uses of several commonly used grinding wheels. The outer diameter of the grinding wheel should be selected as large as possible to increase the peripheral speed of the grinding wheel, which is beneficial to improving grinding productivity and surface roughness. In addition, if the stiffness and power of the machine tool permit, if you choose a grinding wheel with a larger width, you can also achieve the effect of improving productivity and reducing roughness. However, when grinding highly heat-sensitive materials, in order to avoid burns and burns on the workpiece surface If cracks occur, the width of the grinding wheel should be appropriately reduced.