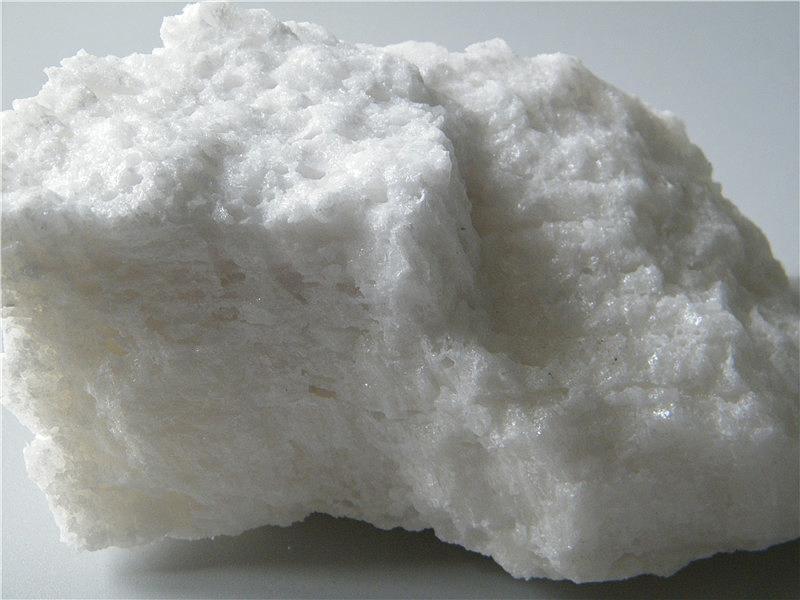

Zirconium corundum

FUSED ZIRCONIA ALUMINA is made from alumina and zirconium oxide as raw materials and is smelted in an electric arc furnace at temperatures above 2000°C. Introduction Classification of zirconium corundum: According to the ZrO2 content, zirconium corundum generally includes low zirconium corundum (ZrO2 10%~15%), medium zirconium corundum (ZrO2 25%) and high zirconium corundum (ZrO2 40%). Chemical composition of zirconium corundum: The main crystal phase of zirconium corundum is α-Al2O3, the secondary crystal phase is baddeleyite, and there is also a small amount of glass phase. Physical properties of zirconium corundum: Zirconium corundum has a tough texture, dense structure, high strength, and good thermal shock resistance. It is generally gray-brown in color. Zirconium corundum uses Zirconium corundum has good melt corrosion resistance. As a high-grade abrasive, it can make high-performance heavy-duty grinding wheels and has a good grinding effect on steel parts, cast iron parts, heat-resistant steel, and various alloy materials; in addition, Zirconium corundum is also a high-grade refractory raw material. It is an ideal material for making high-performance sliding nozzles and immersed nozzles. It can also be used to make zirconium corundum bricks for glass melting furnaces. Physical and chemical properties chemical properties Both sexes Density (g/cm3) ≥4.00 Moh's hardness ≥9.0 melting point 1850°C