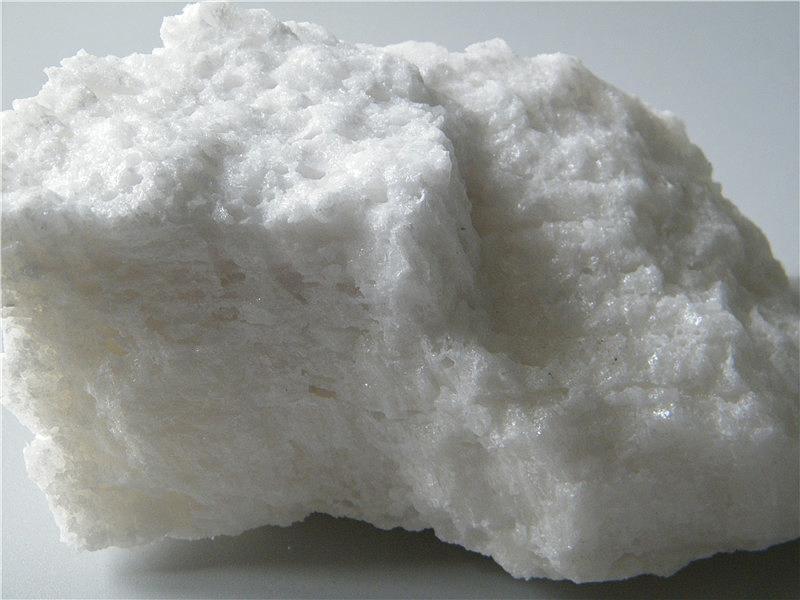

Fused white corundum

Abrasive tools made of white corundum are suitable for grinding high carbon steel, high speed steel and quenched steel. White corundum abrasives and sub-white corundum abrasives can be used as grinding and polishing materials, precision casting sand, spray materials, chemical catalyst carriers, special ceramics, advanced refractory materials, etc. It is made from industrial alumina powder as raw material, which is smelted in an electric arc at a high temperature of over 2000 degrees and then cooled. It is crushed and shaped, magnetically separated to remove iron, and screened into a variety of particle sizes. Its texture is dense and hard, and the particles form sharp angles. It is suitable for manufacturing ceramics, resin-bonded abrasives, grinding, polishing, sandblasting, precision casting (special corundum for precision casting), etc. It can also be used to manufacture advanced refractory materials. The code name "WA" is consistent with international standards and national standards. Most For export, there is also a certain amount of supply to domestic users. Density is divided into two types, one is the packing density of white corundum, and the other is the true density of white corundum. The packing density is: 1.53~1.99g/cm3. The packing density of abrasives is related to the particle size, particle size composition, variety, particle shape and other factors of the abrasives. Generally speaking, coarse-grained abrasives have a higher packing density than fine-grained abrasives, and mixed-grained abrasives The packing density is greater than the single particle size density. The particle density is: 3.95~4.0g/cm3. In recent years, the true density of Zhengzhou Dayu Company’s special corundum for precision casting has reached 4.1/cm3. The true density of the abrasive refers to the mass of the abrasive contained in the unit volume (excluding the volume of open pores) Physical properties Crystal form: Trigonal crystal system Chemical properties: Amphiphilic Reacts with acid: slightly corroded in aqua regia and hydrofluoric acid Reacts with alkali: only slightly reacts with strong alkali hot solution Redox effect: No Density: 3.90 g/cm3 Hardness: Knupp hardness 2000-2200 Kg/mm2, Mohs hardness 9.0 color: White Melting point: 2250 C Maximum operating temperature: 1900 C Specific heat: (Cal/g. C) 0.26 (20 - 90 C) Thermal conductivity coefficient Room temperature 900 C (Cal/cm3. sec. C) Refractive index: e=1.760 w=1.768 (Na line) Resistivity: 30 C 300 C 900 C 1600 C (cm) 10 16 10 13 10 5 10 4 Linear expansion coefficient: 7 - 9 (0 - 1600 C) Product Usage White corundum is suitable for surface beautification treatment of various high-end products, crafts or hardware products. After sandblasting, the surface will be white without any impurities, eliminating the trouble of cleaning. Fine white corundum can be used as a polishing tool. It can also be used as a variety of product additives. 1. Surface processing: metal oxide layer, carbide black skin, metal or non-metal surface rust removal, such as gravity die-casting mold, rubber mold oxide or release agent removal, ceramic surface black spots, uranium color removal, painting Rebirth. 2. Beautification processing: Matte or matte processing of various gold, K gold jewelry, precious metal products, matte processing of crystal, glass, corrugated, acrylic and other non-metals, and can make the surface of the processed object become metallic luster. 3. Etching processing: etching art for jade, crystal, agate, semi-precious stones, seals, elegant stones, antiques, marble tombstones, ceramics, wood, bamboo chips, etc. 4. Pre-treatment processing: Teflon (TEFLON), PU, rubber, plastic coating, rubber roller (ROLLER), electroplating, metal spray welding, titanium plating and other pre-processing to increase surface adhesion. 5. Burr processing: Burr removal of bakelite, plastic, zinc, aluminum die-casting products, electronic parts, magnetic cores, etc. 6. Stress relief processing: Stress relief processing for parts in aerospace, national defense, precision industry, rust removal, paint removal and matting, renovation, etc.