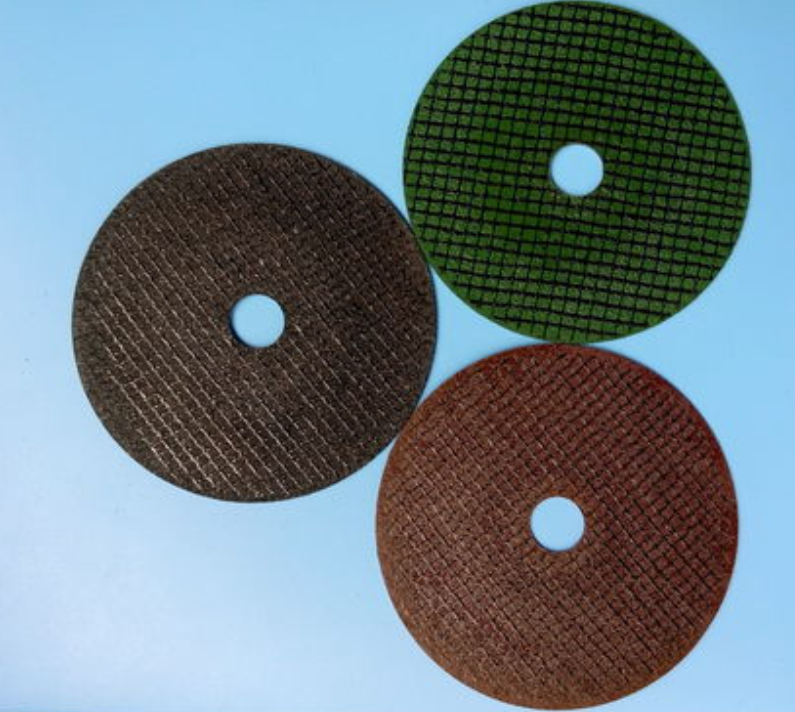

Abrasive cutting disc

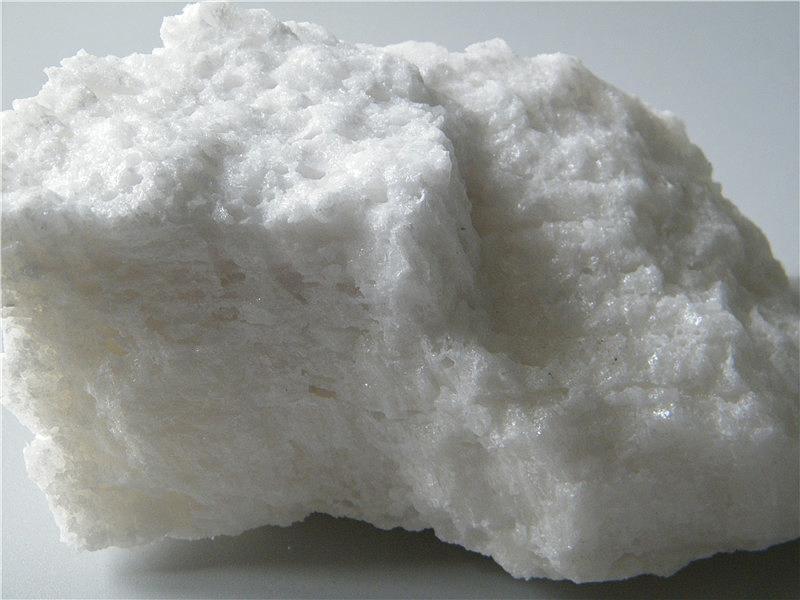

The cutting blade belongs to the grinding wheel. It is made of abrasives and binder resin and is used to cut thin sheets of ordinary steel, stainless steel, and non-metallic materials. It is divided into resin cutting blades and diamond cutting blades. use It uses glass fiber and resin as reinforced bonding material, which has high tensile, impact resistance and bending strength. It is widely used in the production and blanking of ordinary steel, stainless steel metal and non-metallic materials. Excellent materials and exquisite craftsmanship ensure the processing of different materials. High cutting efficiency of the workpiece and the best economic effect. Classification Cutting blades are mainly divided into fiber resin cutting blades and diamond cutting blades according to their materials. 1. The resin cutting blade uses resin as the binding agent, fiberglass mesh as the ribs, and combines a variety of materials. The cutting performance is particularly remarkable for difficult-to-cut materials such as alloy steel and stainless steel. The two cutting methods, dry and wet, make the cutting accuracy more stable. At the same time, the choice of material and hardness of the cutting blade can greatly improve your cutting efficiency and save your production costs. 2. The diamond cutting blade is a cutting tool that is widely used in the processing of hard and brittle materials such as stone, concrete, precast panels, new and old roads, ceramics, etc. Diamond cutting blades are mainly composed of two parts; the base body and the cutter head. The base body is the main supporting part of the bonded cutter head, while the cutter head is the part that cuts during use. The cutter head will be continuously consumed during use. , but the matrix does not. The reason why the cutter head can cut is because it contains diamond. As the hardest substance, diamond friction cuts the object to be processed in the cutter head, while the diamond particles are wrapped in the cutter head by metal. internal. Choice of cutting blades Where to use cutting blades First of all, choose according to the different occasions where the cutting blade is used. Cutting blades can be divided into cutting and grinding types based on the way they are used. Most cutting machines are fixed and mobile. The power of the machines is divided into high power (>5.5KW) and low power (<3KW). The cutting speed will also be divided into two types: high-speed cutting (>80m/s) and normal cutting. In addition, a variety of materials can be cut during cutting, such as stainless steel, titanium alloy, ordinary steel, sticky metal, high carbon steel, non-metal, etc. Different usage scenarios have different performance requirements for cutting blades, so it is important to choose a reasonable cutting blade. We should choose the cutting blade according to the occasion of our own use, which can increase the safety factor, improve work efficiency and reduce our use costs. Selection of cutting blades for ordinary cutting machines Ordinary cutting machines usually refer to cutting machines with a fixed cutting table, power <3KW, and rotation speed of 2900 rpm. Ordinary cutting machines usually cut workpieces with diameters less than 50mm. However, due to the low cutting power and in order to reduce radial frictional resistance, we usually choose a cutting blade with a thickness of 3.2mm. This way the cutting blade is thinner and has a certain degree of elasticity, making it feel sharper when cutting. In order to reduce lateral frictional resistance, the products of Sanxiong Abrasives Company change surface contact into point contact, and the formula system adds lubricant, which can greatly reduce the friction heat generated during cutting and improve the durability and sharpness of the cutting blade. High power cutting machine cutting blade selection High-power cutting machines are usually used when the cutting table power is greater than 5.5KW, the rotation speed reaches 2800 rpm, and the diameter of the workpiece is large. Because the torque force during cutting is relatively large, the damage to the cutting blade is also relatively large, so the cutting blade is required to have a certain degree of rigidity. We usually choose a cutting blade with a thickness of 3.8mm. At the same time, due to the large cutting diameter, the resistance of the cutting blade will also increase, and the temperature generated on the cutting surface will be very high, so it is very important to reduce the cutting temperature. If possible, add water to cool down when cutting. Experiments have shown that if water is added for cooling during cutting, the durability of the cutting blade can be increased by 1.5-2 times. However, in some cases there is no condition to add water for cooling. Therefore, when Jixiang Abrasives produces high-power cutting discs, powdery coolant will be added according to the formula to help reduce the temperature generated during cutting and at the same time increase the service life of the cutting discs. development trend With the increasing number of mechanical industries, more mechanical products need to be processed. Usually, each product needs to be cut and formed first, and then undergo subsequent grinding and polishing. After a series of processes, it finally becomes a mature product. products, so what kind of cutting disc products will become the leader in the industry? It uses glass fiber and resin as reinforced bonding material, which has high tensile, impact resistance and bending strength. It is widely used in the production and blanking of ordinary steel, stainless steel metal and non-metallic materials. Excellent materials and exquisite craftsmanship ensure the processing of different materials. High cutting efficiency of the workpiece and the best economic effect. First, the hardness of the cutting blade. In the future, there will be more and more new metal products, so the hardness requirements of the cutting blade products will also increase. The hardness of the cutting blade product determines everything about the product, which is brought by super-hard abrasives. The high-precision and high-efficiency grinding effect has been widely recognized. Second, the improvement of the physical structure of abrasive tools, such as increasing the number of abrasive grains acting on the workpiece per unit time, increasing the average grinding length, and increasing the grinding contact surface, all of which change the amount of grinding removed per unit time, effectively It improves efficiency; only cutting discs that truly improve product efficiency can truly grasp the future market. With the development of the machinery industry in the future, more and more cutting disc industries are beginning to approach this market, and many companies have begun to update their product technologies, hoping to develop more good products.